Adwatec has created a simulation model for cooling system development and optimization in cooperation with Lappeenranta University of Technology. Simulation model has been tested and verified for B and C series cooling stations and is also available for L-series cooling stations. This enables us to create even better and more accurate cooling solutions for our customers.

Cooling system pressure losses are often estimations with high safety margins. This may lead to oversizing the pumps and other cooling system components. The oversizing increases material costs and energy consumption. The cooling stations are often located in areas with very strict space restrictions. Cooling station component optimization ensures that the cooling station footprint is minimized as well.

How the optimization works?

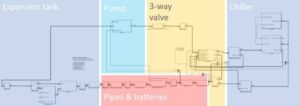

The pressure losses are optimized by selecting the pipe components that are used in a project. Other components are added to the simulation model and the simulation is good to go.

Pressure heads, flow rates and energy consumption can be monitored in the model. Also, the pump models can be changed between simulations with just a couple of clicks. Optimization results can be compared with each other and the most suitable solution can be selected.

Changes and comparisons can be done for all components in the cooling system. For example:

- If pressure losses with selected flow rates are high, the pipe component dimensions should be increased.

- If statical pressure increases to abnormal level with coolant temperature increase, the expansion tank volume should be increased.

A comparison with temperatures, pressures and flow rates can be done at any location of the cooling system. Changing one component in the cooling system may have an impact to other parts in the system. By following all the characteristic parameters in the cooling system the end result can be optimized and the risk of errors is minimized.

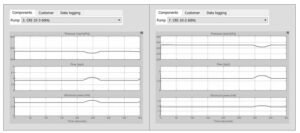

The cooling system sizing is often done for the worst case scenarios. However, the ambient temperature and the heat load of the cooling loads may vary a lot. The variating temperatures and heat loads can be included in the simulation model by feeding the temperature and heat load profiles as timeseries for the simulation model.

When using water-to-air (W2A) heat exchanger the ambient temperature has an important role in the cooling process: the cooling capacity varies a lot with the temperature change. At the same time the heat load may vary making the heating/cooling profile very complicated. The simulation checks that the temperature control is capable of handling the changing heat loads and cooling powers in complex cooling scenarios.

If it is known that heat load or ambient temperature varies in rapid phases, the coolant temperature variation can be tuned down by changing the temperature control parameters.

Pros of using simulation model

- Faster and more precise technical specifications at offering stage

- Minimization of energy consumption and cooling station foot print

- Investment cost optimization for pump, expansion tank, pipeline, heat exchanger, buffer tank, compressor unit and other components

- Possibility to study the cooling station heat load-, temperature– and power consumption profile in changing environment.

- Possibility to tune temperature control parameters in advance to ease the commissioning

We would be pleased to offer you and your project our consulting services! For more information, please, contact our cooling experts:

Veikko Verronen, R&D Engineer, Adwatec Oy

+358 40 771 9460

veikko.verronen@adwatec.com

Teemu Alajoki, Technical Manager, Adwatec Oy

+358 40 845 7150

teemu.alajoki@adwatec.com