Cooling solution article published in Electric & Hybrid Marine Technology International Magazine in April 2021. Click the image for magazine version.

Marine electrification trend is increasingly being applied to smaller vessels, with variable frequency drives and battery systems being used increasingly in workboats, river and lake boats and yachts. Traditional electrical switchgear cabinets may not be suitable in these vessel applications due to less physical space being available.

Traditionally, liquid cooling systems have been part of the electrical switchgear and drives package with the liquid cooling unit installed in a switchgear in its own separate cubicle. As a result, the total height of the cubicle has been used for cooling solution.

In smaller vessels there is less space available and therefore new solutions are required to fit the required electrical gear on board. For this purpose, a modular cooling solution is the way to go.

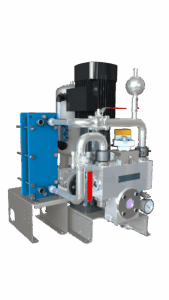

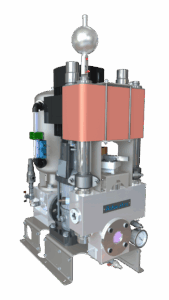

The CCE56S cooling station can be equipped with a different heat exchanger and contronl systen modules. The seawater-resistant heat exhanger is sitauted beside the pump for fast and easy maintenance.

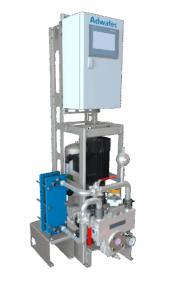

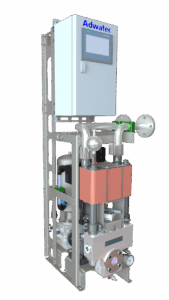

Instead of installing one complete cooling cubicle, the cooling unit can be built from modules. The modules may consist of a pump station, water-to-water heat exchanger and electrical control cabinet. These modules may be partly built together or separately installed where there is space available.

Key advantages

In Adwatec’s decentralized solution, the functionality is the same as in a traditional cubicle-built skid unit as the same modules are used. In addition, the Adwatec solution offers several of advantages.

The modules are very small. This is achieved via the use of manifolds instead of complex pipe arrangements. The manifold construction reduces the number of components used, and several operational functions can be combined in one.

The construction is marine-robust and very reliable. Only stainless-steel materials and proven components are used. Fewer components means fewer risky connections.

The expansion tank with liquid and air in the same space makes it possible to monitor the amount of both in the system. As there are no rubber bags or bladders in use, the construction is extremely long lasting.

The expansion tank and Adwatec’s de-aerating concept result in a very fast commissioning time. The difference between this and traditional system designs may be significant: commissioning in two hours instead of 20.

The CCE56S cooling station with a standars stainless-steel heat exchanger. A control cabinet can be mounted in the same frame or delivered as a loose item.

In marine cooling applications, reliability is something that should never be compromised. Adwatec has delivered several hundred cooling units for vessels operating in a wide range of sailing conditions, from arctic cold to tropical heat. This experience has been applied to the modular solution, and the same levels of reliability are now available for all vessels, from small to large.

WORDS: Heikki Mustonen, Managing Director, Adwatec Oy

+358 50 477 8685

heikki.mustonen@adwatec.com

Read more articles