other applications:

industrial drives

Liquid cooling for demanding conditions

Industrial drives are used to control the speed, torque, and direction of electric motors in various applications, from manufacturing to automation. They are essential for optimizing the performance and efficiency of industrial processes. Robust cooling solutions are necessary to manage the heat generated by power electronics and motors, ensuring reliable operation and preventing overheating under heavy loads.

Liquid cooling systems are becoming more common to ensure effective heat dissipation and maintain the reliability of industrial drives, especially under the following conditions:

- High Power Levels: High-power industrial drives, such as medium-voltage frequency converters, generate significant heat that is challenging to manage with air cooling alone. Liquid cooling is more efficient in these cases.

- Limited Space: Liquid cooling allows for a more compact design, as it is more efficient than air cooling and requires less space for cooling components.

- Noise Requirements: Liquid cooling is quieter than air cooling, which is important in environments where noise levels are a critical factor.

- Demanding Environmental Conditions: Industrial drives operating in harsh environments, such as high temperatures or dusty conditions, benefit from liquid cooling because it is less susceptible to environmental influences.

- Long-term Reliability: Liquid cooling helps maintain the temperature of industrial drives at optimal levels, extending their lifespan and improving reliability.

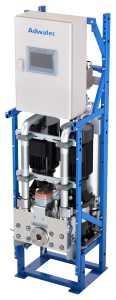

Adwatec solution

Adwatec provides a series of effective cooling stations for the closed-loop systems with high cooling performance within a small footprint. Adwatec cooling stations are pre-engineered, highly productized units providing high reliability essential for industrial drive systems cooling.

Products for industrial drives

Design your own solution

Adwatec water cooling solution configurator is the first online application that allows you to design your water cooling station easily whenever, wherever.

Why choose Adwatec?

Sustainability

Adwatec is sustainable because it runs its business in a sustainable way, provides sustainable products, and delivers these products to sustainable applications.

Customisation

Adwatec offers modular cooling solutions, designed for flexible integration within switchgear cabinets or custom configurations. We provide both standard and custom connection pipes, all manufactured to high industrial standards.

Ease of work

We prioritize customer ease with open resources, a product configurator, automated processes, and round-the-clock project support.

Reliability

With 25+ years of water cooling experience, we deliver rigorously tested, tailored solutions for diverse applications.

Lifecycle Cost

Our compact, correctly sized solutions minimize costs and energy use. Marine approvals, easy installation, and eco-mode control ensure long-term efficiency and reduced maintenance.

Need assistance?

I’m here to help

Sales Manager, Marine