Without cooling systems, today’s shipping industry, with its massive engines and abundance of on-board electronic equipment, would not exist. Without adequate cooling, these components can overheat, leading to equipment failure or even potential fires. Efficient cooling is therefore critical to the smooth operation of propulsion systems, generators and other critical equipment, maintaining optimal operating temperatures to ensure the ship functions effectively and safely, while maintaining the reliability and longevity of on-board systems.

Cooling systems are so critical in the maritime industry that they receive special treatment in the IMO’s most important international convention — the International Convention for the Safety of Life at Sea (SOLAS). It states, for example, that ships’ engines and machinery must be equipped with efficient cooling systems to prevent overheating and ensure safe and reliable operation. This includes both primary and back-up cooling systems to maintain appropriate temperatures under different operating conditions. But similar considerations apply to other applications on board a ship: fire safety, ventilation, etc.

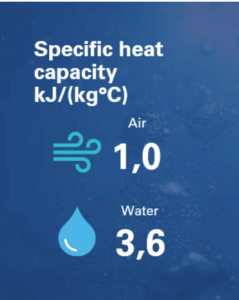

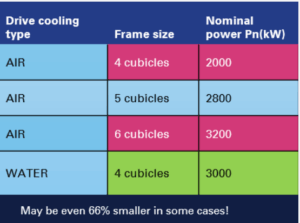

And as science tells us, water cooling systems typically outperform air cooling systems, especially for high power density machines or equipment: water has a higher specific heat capacity than air, allowing it to absorb more heat before its temperature rises; water has a higher thermal conductivity than air, allowing it to transfer heat faster and more effectively; due to its high thermal capacity and conductivity, water can absorb more heat per unit volume than air, etc.

Adwatec water cooling systems:

This is why I have enjoyed writing a series of articles and two previous articles for Adwatec, a leading Finnish manufacturer of water cooling systems. The company has developed some of the most incredibly powerful, but also incredibly small water cooling systems (WCS) for marine applications. Writing for them, exchanging ideas with their people and researching their products has been an admirable learning experience.

Here are some key features of their products:

- Very few wearing parts, very little maintenance: This means that the systems are designed with durable parts that experience minimal degradation over time, resulting in fewer breakdowns and reduced maintenance requirements. This increases reliability and reduces operating costs associated with frequent repairs and parts replacement.

- Materials are robust and components are supplied by reputable companies: The system is constructed from robust materials and sourced from reputable suppliers known for their quality. This ensures the cooling system can withstand the harsh marine environment and maintain high performance, contributing to the overall durability and reliability of the equipment.

- Proper sizing – long life: Proper sizing of the cooling system ensures that it operates within its optimum performance range, reducing stress on components. This correct sizing results in a longer operating life as the system is neither over- nor under-utilised, promoting efficient and sustainable performance.

- Small size – small footprint: The compact design of the cooling system minimises the space it occupies on the ship. This small footprint is beneficial in the often confined environment on board, allowing more efficient use of available space for other essential equipment or cargo.

- Small footprint – lower cost: The compact design of the cooling system minimises the space it occupies on the ship, reducing the need for extensive structural modifications and optimising space utilisation. This efficient use of space translates into lower installation and operating costs, making the system a cost-effective solution for ship operators.

- Easy installation and commissioning: The system is designed for easy installation and commissioning, saving significant time and labour costs during these initial stages. This ease of installation also facilitates faster integration into the ship’s systems and reduces downtime.

- Save time during installation and later during maintenance: The user-friendly design not only simplifies initial installation, but also makes routine maintenance quicker and easier. This reduces overall operational downtime and labour costs, ensuring the system remains efficient and reliable with minimal intervention.

- Eco-mode control: Eco-mode control allows the pumps to operate at lower speeds when full cooling capacity is not required, reducing energy consumption. This feature improves energy efficiency, reduces running costs and contributes to environmental sustainability by conserving energy resources.

In summary: Adwatec likes to say that they take care of the labour, while their customers take care of their core business. By taking care of the labour-intensive aspects of installation and maintenance, the company enables its customers to focus on their core business. A key example of this labour optimisation is the joining of pipes. Adwatec’s prefabricated connection pipes ensure seamless integration into the cooling system. This reduces the need for custom piping and additional labour, simplifying the installation process and further reducing operating costs while maintaining system efficiency.

The C Series:

The example that embodies all the above qualities is the so-called C-series WCS, which has become Adwatec’s best-seller and represents the majority of WCS installed on more than 600 ships to date. Some of the technical characteristics of this model are as follows

- Single or redundant pumps with a maximum flow rate of 750 l/min. The system offers the option of either single or dual pumps delivering up to 750 litres per minute, ensuring reliable and flexible performance for varying cooling requirements. Redundancy for added reliability.

- Electrically operated 3-way valve to eliminate the risk of condensation: An electrically operated 3-way valve is included to prevent condensation, ensuring efficient and safe operation by maintaining optimum moisture control within the refrigerant circuit.

- Refrigerant quality sight glass: The sight glass allows operators to visually inspect the refrigerant for easy monitoring and to ensure it remains in optimum condition for effective system performance.

- AC drive with integrated PLC: Featuring an AC drive with integrated programmable logic controller (PLC), this system offers advanced control and automation capabilities, increasing precision and operational efficiency.

- Expansion tank with level sensors and sight glass for easy coolant level monitoring: The expansion tank includes level sensors and a sight glass for easy monitoring of coolant levels to ensure proper maintenance and prevent potential operational problems caused by low coolant levels.

- Customised connection tubes: The system features customisable connectors to meet specific customer requirements, ensuring seamless integration and compatibility with existing on-board systems.

- Standard safety valve: A safety valve is included as standard, providing vital protection against overpressure conditions, protecting both the refrigeration system and the vessel’s equipment.

- Supplied as an open frame solution or pre-installed in a standard cabinet: The product is available either as an open frame solution for flexible installation or pre-installed in a standard cabinet, offering convenience and ease of use according to customer preference.

I hope you enjoyed this article. You can find previous articles on water cooling systems in my articles section on LinkedIn.

Pablo Rodas-Martini holds a PhD and an MSc from Queen Mary and Westfield College (renamed Queen Mary College), University of London.

Disclosure: Pablo Rodas-Martini is a Contributor to Adwatec.