Brazed vs gasketed heat exchangers

Power electronic cooling applications require heat exchangers to transfer the heat from the cooling circuit to air or another media. Water-to-air heat exchangers can be used if the heat produced by losses can be transferred to outside air. If that is not the case water-to-water heat exchangers come into the picture. In case of water-to-water heat exchanger, the heat losses from the hot power electronics cooling circuit water are transferred through heat exchanger to colder technical or raw water circuit. Despite of the name, water-to-water heat exchangers can be used with various fluids and in most power electronics cooling applications either propylene or ethylene glycol is mixed with water in order to prevent freezing of the cooling media.

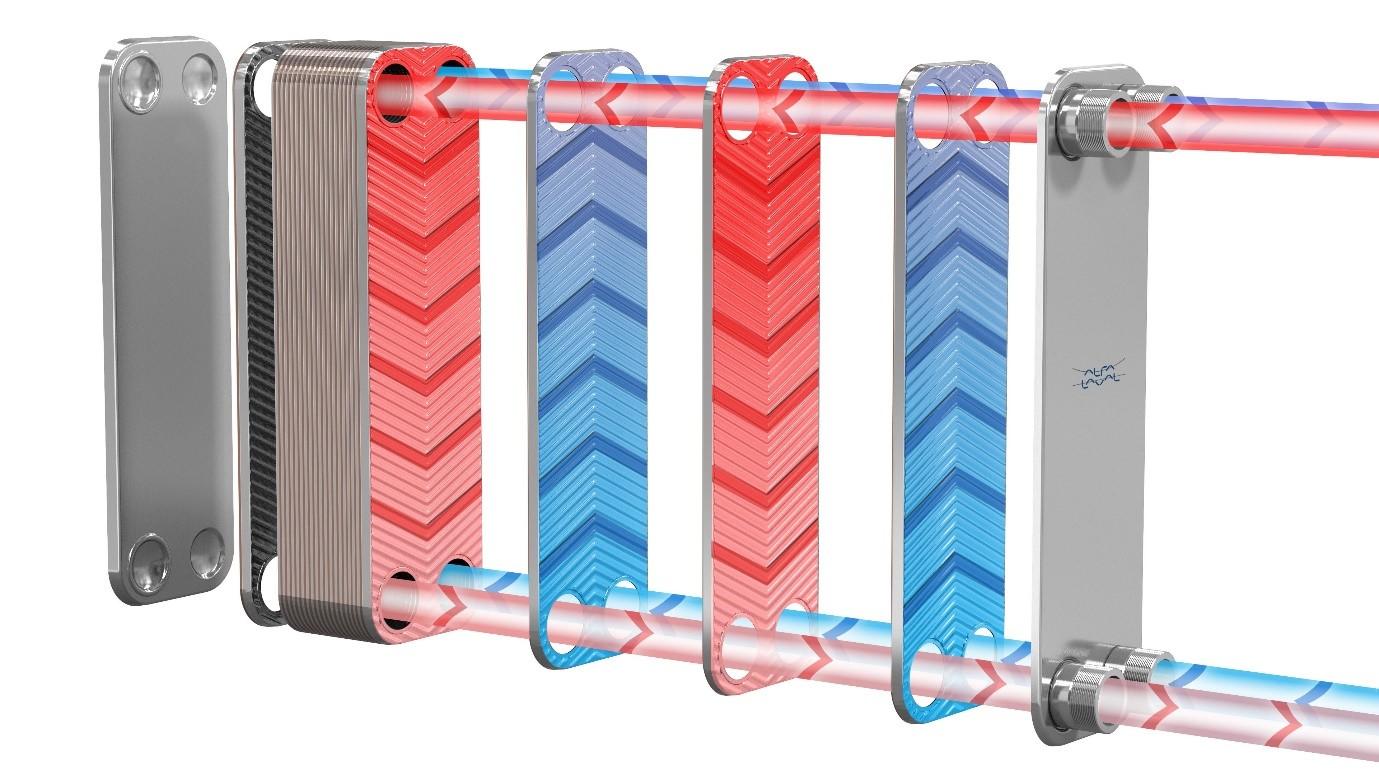

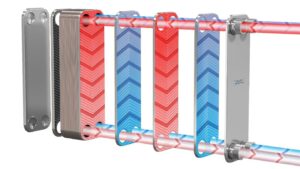

Main principle in water-to-water heat exchangers is to provide large heat transfer surface for two liquid circuits while keeping both liquids apart from mixing into each other. This is achieved with assembling heat transferring metal plates next to each other with narrow space between the plates to provide path for the liquids on each side of the plates. Edges of the plates are sealed in order to prevent liquids from mixing into each other or leaking out from the circuits. The liquids are directed into right space between the plates through inlet and outlet of each liquid circuit.

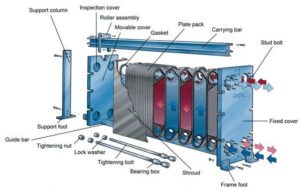

There are two main types of water-to-water heat exchangers commonly used for power electronics cooling applications – brazed heat exchangers and gasketed heat exchangers. Brazed heat exchangers are permanently sealed heat exchangers that consist of heat exchange plates brazed together. There are different materials used for the brazing as well as for the plates for different application and fluids. In gasketed type heat exchangers the plates are assembled with elastomeric gaskets between the plates and pressed together with cover plates at each end holding the stack together with tightening bolts and nuts. Again for different applications the right heat exchanger plate and gasket material needs to be selected for correct operation and longer lifetime of the equipment.

The main differences for power electronic cooling applications between the heat exchanger types are size and maintainability. Size and weight are crucial factors in many of the smallest cooling systems. Therefore, the brazed heat exchanger is commonly selected for marine and other space sensitive applications. Also, the cost of the brazed heat exchanger is often more competitive with smaller flow and heat exchange requirements within few hundred l/min and kW range. For some application there may be variation in technical or raw water purity and it could be foreseen that despite of the filtration of the technical or raw water there could be need for cleaning and maintenance of the heat exchanger. In this case the gasketed heat exchanger may be better choice with the option for maintenance. Also, for large flow and heat exchange requirements the gasketed heat exchange might be the most cost-effective solution.

For each application, the most suitable components with right materials should be selected. In case of questions related to the topic or other cooling needs, contact our experts for more information.

Learn more about Adwatec water cooling solutions

WORDS: Pauli Halonen, Sales Manager, Adwatec Oy

+358 50 410 8338

pauli.halonen@adwatec.com