Temperature control article published in Electric & Hybrid Marine Technology International Magazine in July 2020.

Temperature control

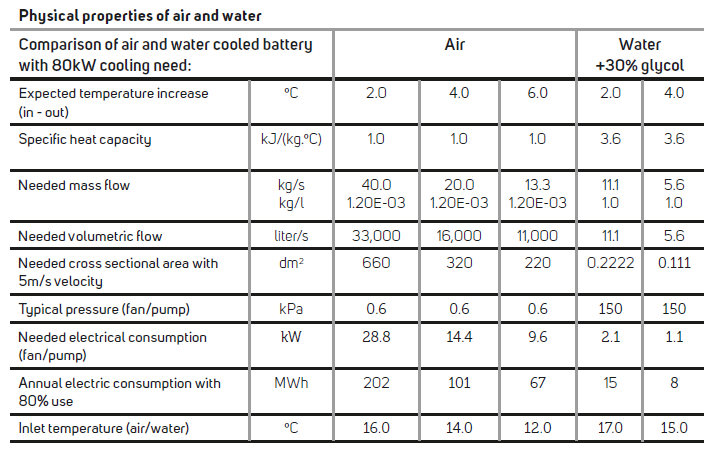

Water cooling can be used to dissipate heat generated at the source and is thus the most effective for battery applications. Traditionally air cooling has been the most widely used method of thermal management, but water cooling is becoming more common. While the batteries are in light use, up to 1 C-value (full capacity is charged or discharged in one hour), air cooling is usually efficient enough. When the C-value is higher, the heat energy generated increases. Air has a very low specific heat capacity, which means that a large volume of air is needed to ensure cooling. Big air volumes need large air channels around all the battery cells, which increases the dimensions of the stacks. One way to decrease the air volume is to decrease the incoming air temperature, but this leads to unstable battery temperatures and to a risk of water condensation.

With any high-power electrics there is always a safety risk, and there have been concerns about the safety of water cooling in batteries. A water cooling system must therefore be carefully separated from the electrical circuit. In a theoretical battery fire, high-velocity air releases oxygen into the fire, while the water continues to cool the batteries – preventing them from overheating. Air cooling can’t be used at this stage as it would fuel the fire. The cooling system must be a pressurized closed-loop circuit to keep the coolant and the system clean. Good-quality components with the right materials must be used. Adwatec’s modern water cooling stations are easy to configure thanks to their modular design.

If enough low-temperature technical water or sea water is available, it can be used to cool the coolant. This free cooling is not often available in a typical marine battery application and a chiller must be added to achieve the right coolant temperature. The water cooling

can be used for air cooled batteries as well. In such an application the water cooling circuit is connected to the air heat exchanger in the battery room to keep the air cooling system at the right temperature.

The physical properties

The psysical properties of water are much more conducive to the application. In fact, its heat capacity is higher than that of any other liquid or gas on Earth. One liter of water can draw 3,000 times more energy from a battery than one liter of air. As air is more thermally isolating than water it is more difficult to get heat from the batteries into the air than into water. For these reasons, the cooling power of water is superior to that of air. Ultimately water cooling enables smaller batteries to be realized and bigger C-values employed. Electrical power required for the cooling process is often taken from the batteries. Thus the lower the electrical power consumption of the cooling system, the more battery capacity is available for other purposes. Circulation of air round a battery requires 10 times more electricity than water circulation.

Concerns about safety

With any high-power electrics there is always a safety risk, and there have been concerns about the safety of water cooling in batteries. A water cooling system must therefore be carefully separated from the electrical circuit. In a theoretical battery fire, high-velocity air releases oxygen into the fire, while the water continues to cool the batteries – preventing them from overheating. Air cooling can’t be used at this stage as it would fuel the fire. The cooling system must be a pressurized closed-loop circuit to keep the coolant and the system clean. Good-quality components with the right materials must be used. Adwatec’s modern water cooling stations are easy to configure thanks to their modular design.

If enough low-temperature technical water or sea water is available, it can be used to cool the coolant. This free cooling is not often available in a typical marine battery application and a chiller must be added to achieve the right coolant temperature. The water cooling can be used for air cooled batteries as well. In such an application the water cooling circuit is connected to the air heat exchanger in the battery room to keep the air cooling system at the right temperature.

WORDS: Arto Verronen, Strategist, Member of the Board

For more information please contact Ismo Lehtonen, Sales and Marketing Director

+358 40 669 2220

ismo.lehtonen@adwatec.com